Task

Optimal cutting of linear material, minimizing the length of the trimmings. As initial data, use the length of the workpiece, the width of the cut and the list of parts to be made, indicating the linear size and quantity. In the calculation, use the available blanks of various lengths, which are also presented in a list indicating their length and quantity.

Solution

The task is a classic one, therefore, you can find a lot of detailed discussions on the web on how to solve it correctly using various mathematical methods, including using MS Excel. There are also many online resources with online calculators, paid and free. Nevertheless, I decided to offer my own version of the implementation of the calculation using the My Visual Database (MVDB) platform as a tool for creating the corresponding program. In the future, I plan to use the considered method as part of the “Production” program, combining it with the warehouse accounting system.

To determine the optimal layout of parts (cut maps), a complete enumeration algorithm is used, supplemented by optimization conditions: cutting off enumeration options with a deliberately poor result and early exit when an ideal option is obtained (zero cut residue). That is, in the loop, all possible options for the layout of parts are sorted out until the best option with the minimum cutoff value is found or the optimization conditions are triggered.

Then it is determined how many times the resulting cut map can be used to produce the required number of parts. Then the map is added to the resulting list.

In the case where we have several blanks of different lengths, a strategy of “keep liquid stock” is used, that is, short blanks go under the knife first, since long trims are more likely to be used in the next order, and small trims usually go to junk. From a mathematical point of view, this approach does not guarantee a minimum percentage of losses during sawing, but it ensures the minimization of purchases of materials for the current order and the maximum use of available stocks.

Implementation

To store the initial data and the result, several database tables are used, and to enumerate the options, the data is loaded into RAM. Unfortunately, MVDB does not support structures (Record), so dynamic arrays are used to store data – a separate array for each value (when implementing this algorithm in other languages, it will be a little more elegant).

After the arrays are initialized and data is loaded into them from the database tables, two repeat..until loops are organized. External – for sorting blanks, internal – for selecting layout options. The following checks were used as an optimization in the inner loop:

if the trim length is zero, then an ideal variant is obtained; early exit from the cycle

if the trim length is negative, then you need to go to the enumeration of smaller parts

However, from words to deeds: below is a script with detailed comments that implements this algorithm.

Script

procedure frmCuttingMap_btnCalc_OnClick(Sender: TObject; var Cancel: boolean);

// perform calculation

var

tmpSQL:string; // to store the request text, handy for debugging

tmpQty: integer; // number of details

tmpDetLen: array of integer; // list of part lengths

tmpDetQty: array of integer; // list of number of parts

tmpBQty: integer; // number of blanks

tmpBIndex: integer; // index of the workpiece that the algorithm is currently working with

tmpBlankLen: array of integers; // list of workpiece lengths

tmpBlankQty: array of integer; // list of the number of blanks

tmpmap:string; // slicing map

tmpMapQty: integer; // number of uses of slice map

tmpTestQty: array of integer; // list of the number of parts for the current cut

tmpBestQty: array of integer; // best cut

tmpBestBlankLen: integer; // current length of the workpiece for writing

tmpTestBlankLen: integer; // length of the current workpiece for calculation

tmpTestScrap: integer; // current cut

tmpTestLen: integer; // current length

tmpBestScrap: integer; // best cut

tmpLastIncPos: integer; // last bit that was incremented

tmpIncPos: integer;// digit to increase in the main loop

tmpDataSet: TDataSet;

i,j: integer;

tmpFlag: boolean;

s:string

// slicing matrix modifier

function NextIndex( APos: integer ):boolean;

begin

if APos >= tmpQty then

begin

Result := False;

end

else

begin

Result := True;

tmpTestQty[APos] := tmpTestQty[APos] + 1;

tmpLastIncPos := APos;

if tmpTestQty[APos] > tmpDetQty[APos] then

begin

tmpTestQty[APos] := 0;

Result := NextIndex( APos + 1);

end;

end;

end;

//

begin

Progress(0,0,'Searching for a solution...',True);

try

// save settings for kerf width

CutWidth := Trunc( frmCuttingMap.edtCutWidth.Value );

IniFile_Write_Int(APP_PARAMS,'CutWidth',CutWidth);

// initialization

SQLExecute('DELETE FROM cuttingMap'); // clear the results table

//

tmpBQty := SQLExecute('SELECT count(*) FROM blank '); // number of blanks

SetLength( tmpBlankLen, tmpBQty); // list of workpiece lengths

SetLength( tmpBlankQty, tmpBQty); // list of the number of blanks

// data should be sorted in ascending order to ensure a strategy of using short cuts first

SQLQuery('SELECT * FROM blank ORDER BY length ASC',tmpDataSet);

try

for i := 0 to tmpBQty-1 do

begin

tmpBlankLen[i] := tmpDataSet.FieldByName('length').asInteger;

if tmpDataSet.FieldByName('basic').asInteger = 1 then

tmpBlankQty[i] := MAX_QTY

else

tmpBlankQty[i] := tmpDataSet.FieldByName('qty').asInteger;

tmpDataSet.next;

end;

finally

tmpDataSet.Free;

end;

tmpQty := SQLExecute('SELECT count(*) FROM piece '); // number of positions

SetLength(tmpDetLen, tmpQty); // list of part lengths

SetLength( tmpDetQty, tmpQty); // list of number of parts

// start from the first workpiece size

tmpBIndex := 0;

SetLength( tmpTestQty, tmpQty); // list of the number of parts for the current cut

SetLength(tmpBestQty, tmpQty);

// data must be sorted in descending order!

SQLQuery('SELECT * FROM piece ORDER BY length DESC',tmpDataSet);

try

for i := 0 to tmpQty-1 do

begin

tmpDetLen[i] := tmpDataSet.FieldByName('length').asInteger;

tmpDetQty[i] := tmpDataSet.FieldByName('qty').asInteger;

tmpDataSet.next;

end;

finally

tmpDataSet.Free;

end;

//

repeat

tmpTestBlankLen := tmpBlankLen[tmpBIndex];

tmpBestScrap := tmpTestBlankLen; // the best cut is equal to the length of the workpiece

// reset the slicing matrix

for i:=0 to tmpQty-1 do

tmpTestQty[i] := 0;

//

tmpIncPos := 0;

repeat

Application.ProcessMessages;

// early termination

if Progress Cancel then

exit;

if not NextIndex( tmpIncPos ) then // modify the slicing matrix

break // if failed, exit the loop

else

begin

// look at what we got in length

tmpTestLen := 0;

tmpFlag := False;

for i :=0 to tmpQty - 1 do

begin

tmpTestLen := tmpTestLen + (tmpDetLen[i] + CutWidth)* tmpTestQty[i]; // then you need to take into account that the last cut may not be needed...

if tmpTestLen > tmpTestBlankLen then // if the length exceeds the length of the blank, then you can not count further - bad option

begin

tmpFlag := True;

break;

end;

end;

// if there was an overflow, then go to the next option

if tmpFlag then

begin

tmpTestQty[tmpLastIncPos] := 0; // reset the counter in the digit that was last incremented

tmpIncPos := tmpLastIncPos + 1; // we will increase the counter of the next bit, with a smaller weight coefficient

continue;

end;

tmpTestScrap := tmpTestBlankLen - tmpTestLen; // trim

//

if tmpTestScrap < tmpBestScrap then // if best match found

begin

tmpBestScrap := tmpTestScrap;

for i:=0 to tmpQty - 1 do // remember cutting option

tmpBestQty[i] := tmpTestQty[i];

end;

// ideal - zero trim, it doesn't get any better

if tmpBestScrap = 0 then

break;

// prepare for high order increment

tmpIncPos := 0;

end;

until 1=0; // selection cycle; exit if the next matrix cannot be obtained

// there may be a case when the current size is not suitable for calculation

if tmpBestScrap = tmpTestBlankLen then

begin // move to the next size without writing the result

inc(tmpBIndex); // move to the next workpiece

if tmpBIndex < tmpBQty then

begin

continue; // continue...

end

else

begin

break; // blanks ran out...

end;

end;

// draw layout map

tmpmap := '';

for i := 0 to tmpQty - 1 do

for j := 0 to tmpBestQty[i] - 1 do

begin

if tmpMap <> '' then

tmpMap := tmpMap + ': ';

tmpMap := tmpMap + IntToStr( tmpDetLen[ i ] );

end;

//

tmpMapQty := 0;

// count how many times the card can be used

tmpBestBlankLen := tmpTestBlankLen;

repeat

inc(tmpMapQty);

// reduce the residuals by parts

for i := 0 to tmpQty - 1 do

tmpDetQty[i] := tmpDetQty[i] - tmpBestQty[i];

// reduce the balance of blanks

tmpBlankQty[tmpBIndex] := tmpBlankQty[tmpBIndex] - 1;

// now we need to determine if this layout can be used again

tmpFlag := false;

// check for the rest of the parts

for i := 0 to tmpQty - 1 do

if tmpBestQty[i] > tmpDetQty[i] then

begin

tmpFlag := True;

break;

end;

// add a check for the rest of the blanks !!!!!

if tmpBlankQty[tmpBIndex] = 0 then

begin

tmpFlag := True;

inc(tmpBIndex); // move to the next workpiece

end;

until tmpFlag;

// If something was found, then

if tmpBestScrap <> tmpTestBlankLen then

// save the result

SQLExecute('INSERT INTO cuttingMap (blankLength,qty,map,scrap) VALUES ('+IntToStr(tmpBestBlankLen)+','+IntToStr(tmpMapQty)+','+StrToSQL(tmpMap)+','+IntToStr(tmpBestScrap) +')');

// check if there is anything left to make

tmpFlag := false;

for i := 0 to tmpQty - 1 do

if tmpDetQty[i] > 0 then

begin

tmpFlag := True; // yes, found something

break;

end;

// check if there are blanks

if tmpBIndex = tmpBQty then

tmpFlag := False;

until not tmpFlag; // repeat until there is something to make

// update data display

frmCuttingMap.tgrMap.dbUpdate;

finally

progress();

end;

ShowMessage('Calculation completed');

end;Code language: Delphi (delphi)Lines 48 and 213 use the procedure for displaying a progress bar, which is detailed in the “In the name of progress” article.

Line 66 uses the constant MAX_QTY = 1000000; so that for the blanks that can be bought, there is no completion of the outer cycle due to a lack of their quantity.

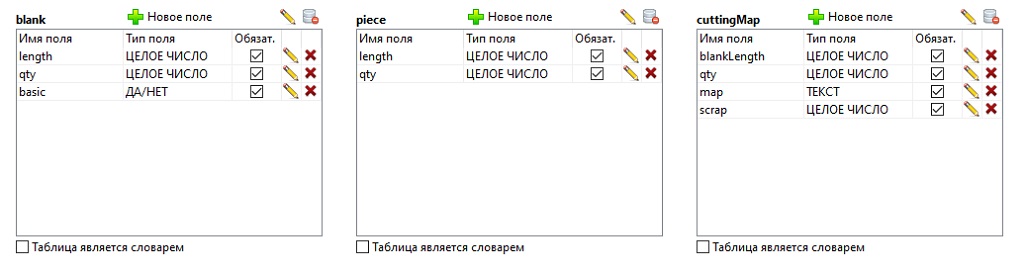

Data structure

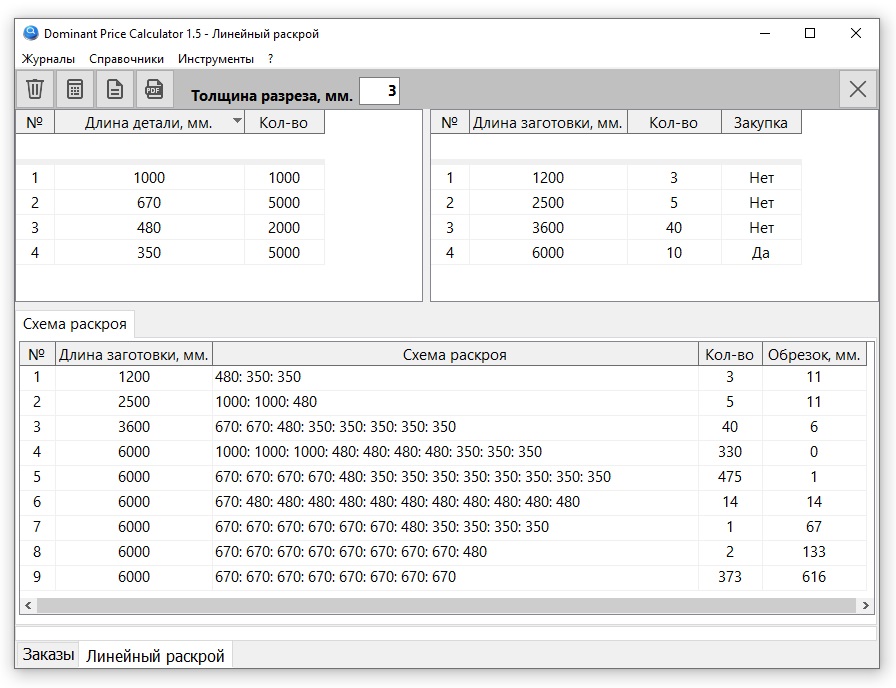

Interface

Tables with enabled data editing mode are used to edit source data (AllowCreate = True, AllowEdut = True, AllowDelete = True).

The buttons on the toolbar are intended for data management:

- Clear input

- Run a calculation

- Generate Document

- Generate PDF

Also on the toolbar there is a field in which you can specify the width of the cut. For a cutter, the width can be 2-3 mm, and when cutting with a laser, the cut width is only 0.1 mm. This means that, in practice, a zero value can be specified in the calculations.

Result

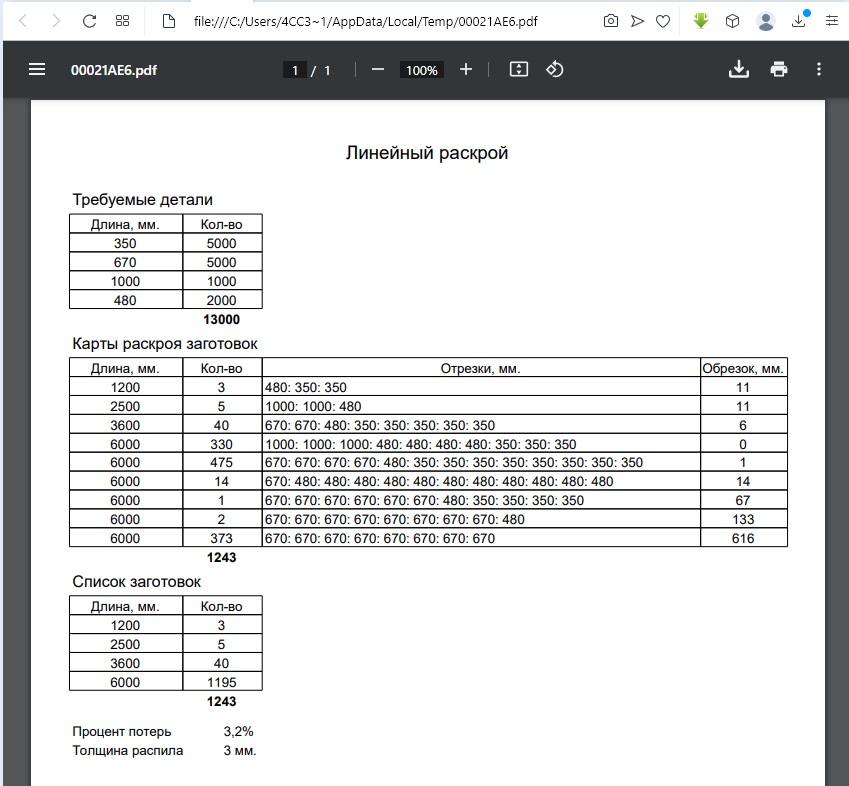

To display the result, a report with three data sources was needed. To generate a report, a script is used that uses the Report_Open() procedure, which is part of the library procedures of the “ClearApp” program. The same script calculates the efficiency of the resulting layout (percentage of losses).

procedure UserApp_LinearCalc_Report( AReportMode: integer );

// linear nesting report

var

tmpDataSets : array of TDataSet;

tmpDSNames: array of string;

tmpStrParam: array of string;

tmpStrParamName: array of string;

tmpReportMode:integer;

tmpReportFileName:string;

tmpSQL:string;

tmpID:string

i: integer;

tmpFileName:string;

begin

tmpReportMode := AReportMode;

tmpReportFileName := 'LinearCalc.fr3';

SetLength( tmpDataSets,3 ); // details, calculation and quantity by size

SetLength( tmpDSNames,3 );

//

SetLength(tmpStrParam, 2); // parameters: usage percentage

SetLength( tmpStrParamName, 2 );

// details

tmpSQL := ' SELECT * FROM piece ';

SQLQuery( tmpSQL, tmpDataSets[0] );

tmpDSNames[0] := 'Piece';

// result

tmpSQL := ' SELECT * FROM cuttingMap ';

SQLQuery( tmpSQL, tmpDataSets[1] );

tmpDSNames[1] := 'CuttingMap';

// summary result

tmpSQL := 'SELECT blankLength, sum(qty) as qty FROM cuttingMap GROUP BY blankLength';

SQLQuery( tmpSQL, tmpDataSets[2] );

tmpDSNames[2] := 'blankSummary';

// options

i := 0;

// Usage factor

tmpStrParamName[i] := 'Percent';

tmpStrParam[i] := FormatFloat('#0.0', ( SQLExecute('SELECT sum( scrap * qty ) FROM cuttingMap') / SQLExecute('SELECT sum( blankLength * qty ) FROM cuttingMap') )*100 )+'% ';

inc(i);

// Usage factor

tmpStrParamName[i] := 'CutWidth';

tmpStrParam[i] := IntToStr(CutWidth)+'mm.';

inc(i);

// call the universal report opening function

tmpFileName := Report_Open( tmpDataSets, tmpDSNames, tmpStrParam, tmpStrParamName, tmpReportMode, tmpReportFileName );

// clean...

Report_FreeDataSets( tmpDataSets );

if AReportMode = RM_PDF then

OpenFile(tmpFileName);

end;Code language: Delphi (delphi)Results

Despite the fact that the My Visual Database project ceased development more than a year ago, it is still suitable for creating convenient and effective business process automation tools.